The Pros and Cons of CRC

A Color Remediation Column Process Overview

The process of using a CRC, Color Remediation Column has become increasingly popular with closed-loop extraction systems, as it provides a simple and cost-effective way to improve the quality of the product being extracted. The process is easy to learn and master, making it ideal for both novice and experienced extractors. Furthermore, the CRC is highly versatile and can be used with many different types of closed-loop systems, making it an ideal choice for any extraction artist.

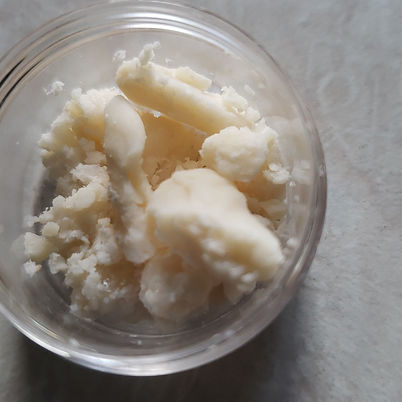

The CRC can be used to remove undesirable colors and odors from cannabis concentrates made from BHO and ethanol extraction processes. By removing the unwanted color elements, concentrate producers can create a product that is more aesthetically pleasing while still maintaining the terpenes and cannabinoid profile of the original flower. The color remediation column technique is especially useful for removing chlorophyll and other plant-based compounds from extracts, resulting in a purer, more potent product. The CRC also helps to reduce the amount of terpenes lost in the extraction process which allows for better flavor retention. Additionally, the CRC can be used to remove residual solvents and contaminants, resulting in a safer and more compliant product.

Inert matrix media is commonly used in CRC to remove undesirable components from an extract. Inert matrix filters can be composed of stainless steel, ceramic, or other materials. These filters are most often used to remove heavy metals and other unwanted impurities.

Activated carbon/charcoal and activated bleaching earth or bentonite clay are both effective filter media for marijuana extraction. Each of these filter media work in different ways to achieve the desired result. Activated carbon/charcoal works by trapping organic molecules and drawing them out of the extract. Activated bleaching earth or bentonite clay works by decolorizing the extract, allowing for the removal of chlorophyll and other impurities.

CRC can be used to separate out desired cannabinoids, terpenes, and flavonoids for a more specific product, such as a CBD isolate. Diatomaceous earth is a fine filter media that helps remove impurities from a marijuana concentrate. Using these filter media, marijuana extraction technicians can achieve a cleaner, more potent end-product.

Overall, the general takeaway is that CRC is an effective, efficient, and cost-effective solution for cannabis extraction companies looking to produce higher quality products. With a color remediation column process, companies can produce safe, pure extracts with improved yield and potency while saving time and money.

CONS OF CRC

What are the negative aspects of using a CRC system? There is a risk that less-than-optimal marijuana extracts can be passed off as higher quality if they are put through a CRC. Unsuspecting customers may be misled by the clearer color, yet the extracts may still have an unpleasant taste and smell. Additionally, the quality of the filtration process can be compromised due to improper ratios and packing practices. This can result in blockages, clogs, and reduced cannabinoid content as well as lower yields for commercial operations.

Excess saturation of the filtration material can cause certain impurities to pass through the filtration levels, resulting in a final product that could be harmful to human health. Inexperienced CRC operators may not stack or pack the filters properly, which could lead to contamination.

For instance, activated carbon from natural sources contains ash that can break down over time and release heavy metals and carcinogenic metabolites into the extract. Furthermore, if there are flow issues, clogging, or an uneven distribution of media in the CRC set-up, an extract of a high quality may be converted into a low cannabinoid, low terpene distillate – NOT ideal.

To ensure efficiency in the CRC process, personnel responsible for extraction should accurately measure the portions of the constituents being handled. The simplest way to decide how much filtration medium should be employed is to evaluate the biomass and determine the cannabinoid content, multiplying it by the mass of the marijuana substance undergoing processing.

REAL WORLD EXAMPLE

Roughly 537 grams of concentrate can be produced from a batch of 4480 grams of extract that has a concentration of 12 percent cannabinoids. The amount of media used in this process needs to be calculated, considering the quality and freshness of the material being used. To minimize the risk of any flow or filtration issues, the recommended size of filter column for a 10-pound run of extract is 6 inches. If the volume increases, two extra inches should be added. Additionally, to encourage effective packing and reduce channeling, operators may wish to consider implementing a hydraulic press on each media layer, although this approach can slightly reduce yield. To further minimize the chances of channeling occurring, the blow-off valve should be set low to avoid back pressure.

BHO closed-loop extraction offers the additional benefit of collecting more terpenes than other solvent extractions, meaning any minimal terpene reduction during color remediation does not cause a pronounced impact on the final product. Those looking to effectively guard against harmful contaminants from permeating the extract should buy filter sheets with adjustable pore sizes that provide strong adsorptive capabilities. Activated carbon can be used to manage odor and hues, both through adsorption and decolorization, yet without staining the

end-product.

A new and effective way for treating BHO and ethanol concentrates is with color remediation cartridges which can lighten the color and scent of your concentrates. That said, it is not always advisable to make such modifications to all strains.

The takeaway here is that CRC seems to be an overall good thing for the BHO extraction industry and process; it’s always a positive when good product can be made better, safer, and done so cost-effectively. BUT as always, it’s important to use critical thinking, and for consumers to do their research when choosing who/what brand(s) to buy their product from.